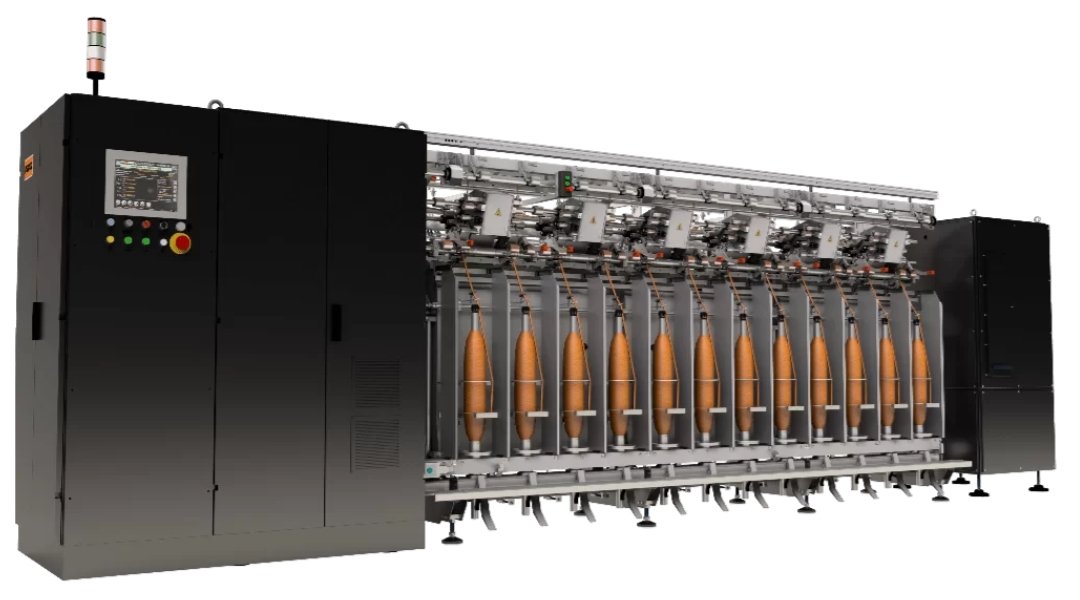

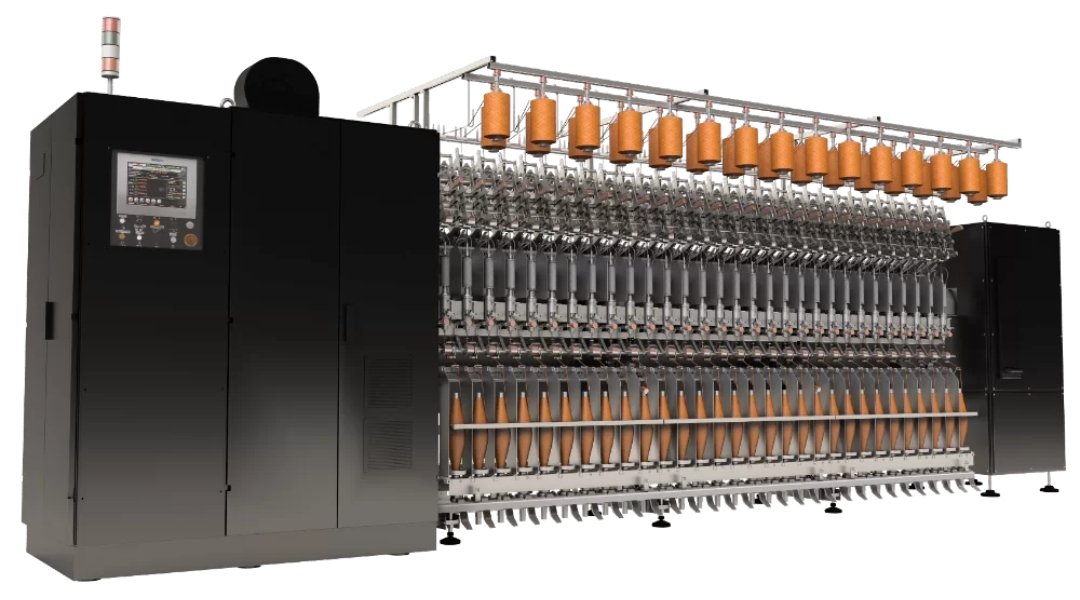

BR-F

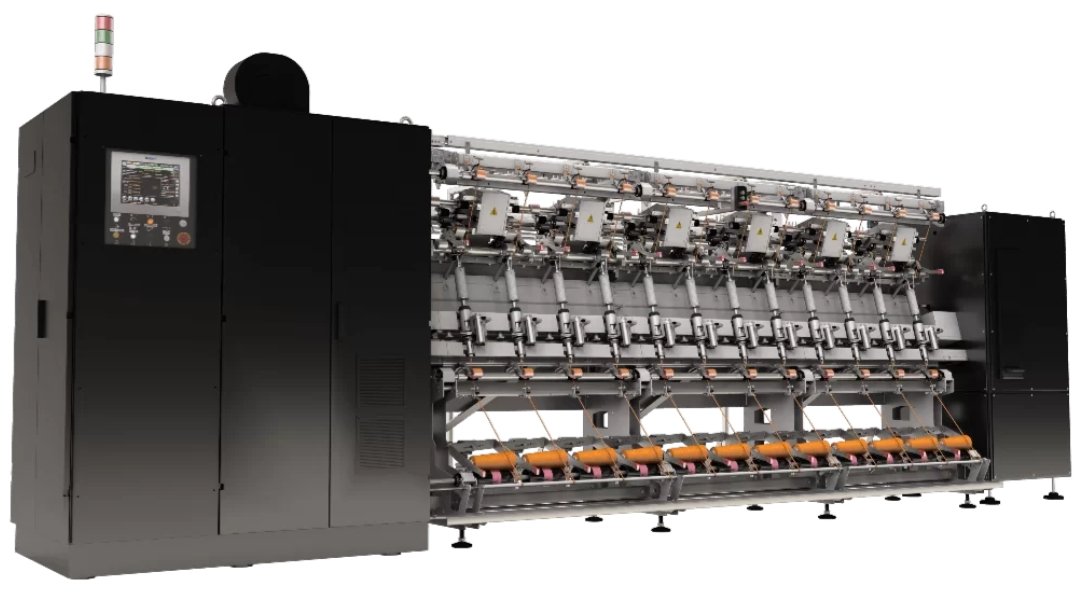

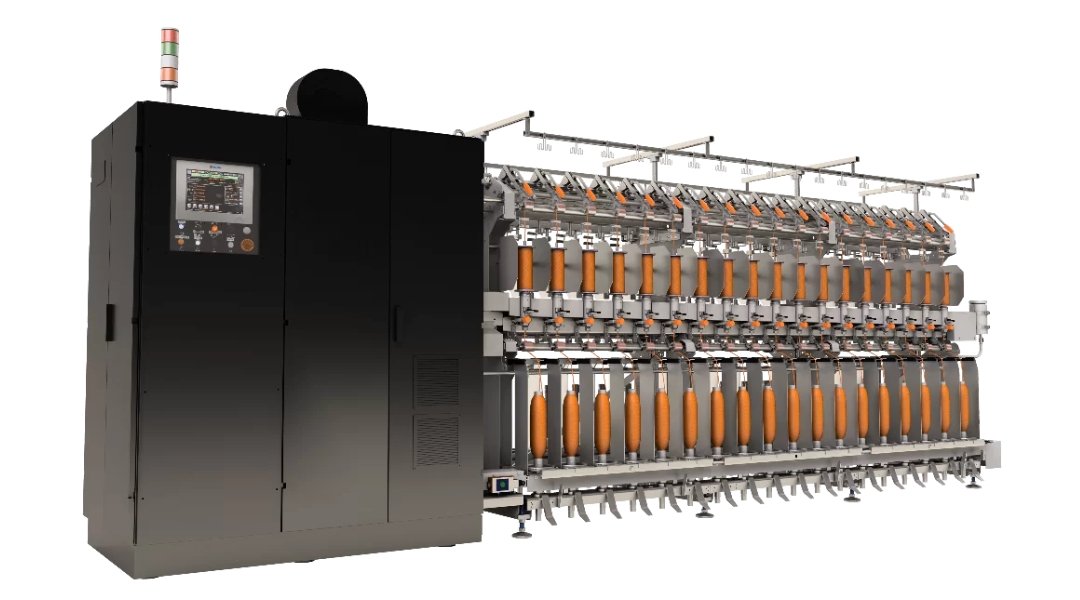

BR-H

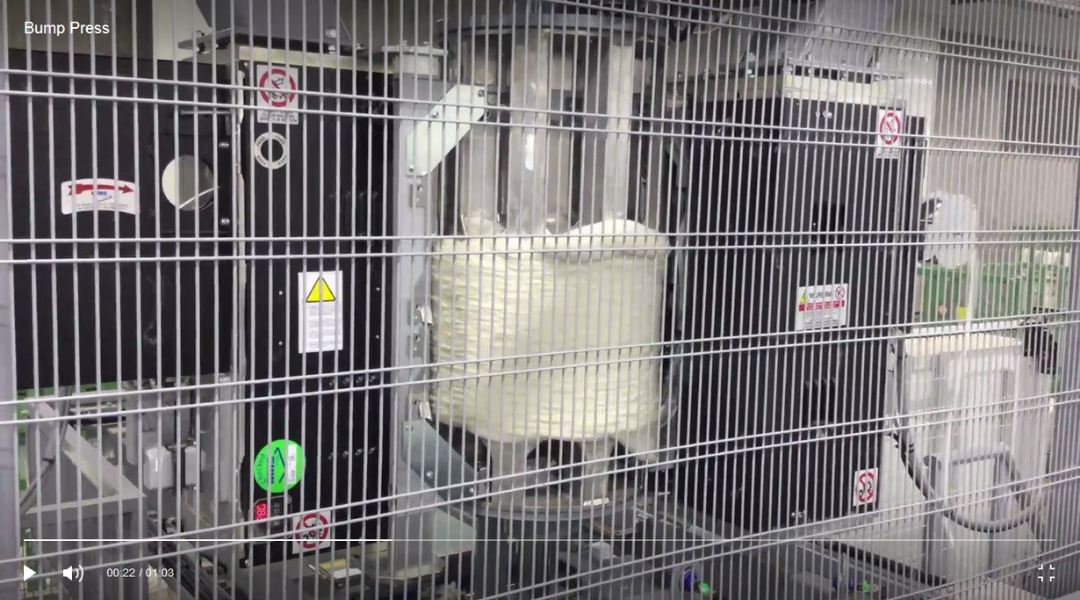

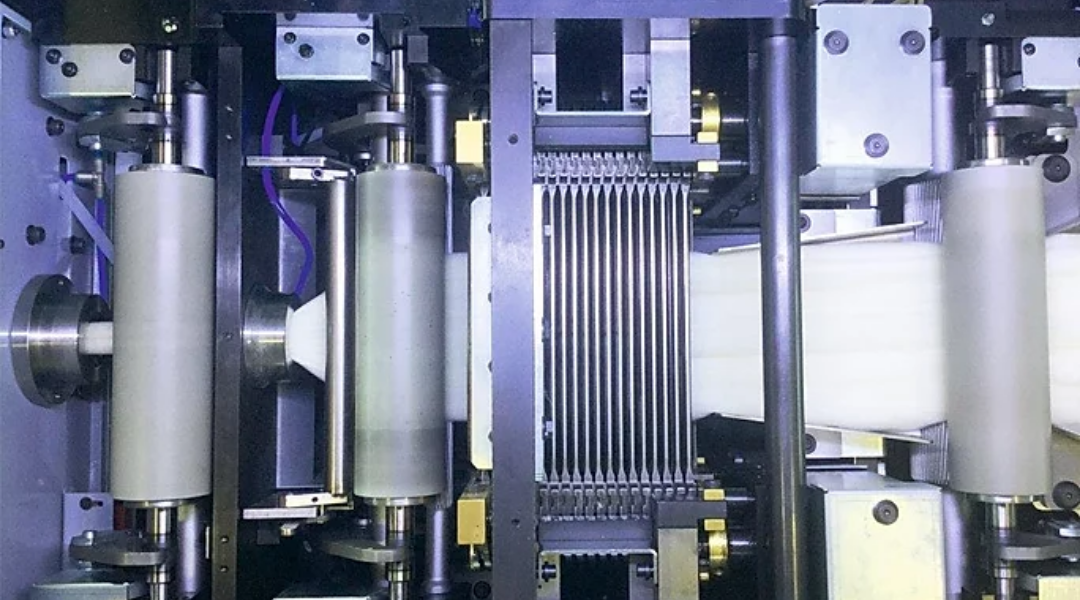

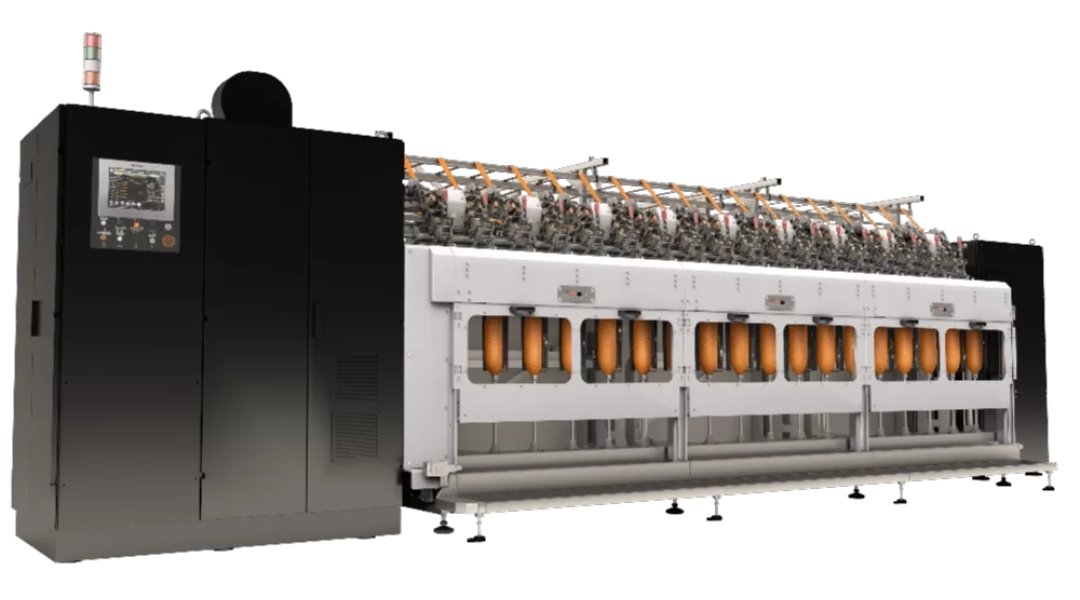

CD 14 - Bump Press

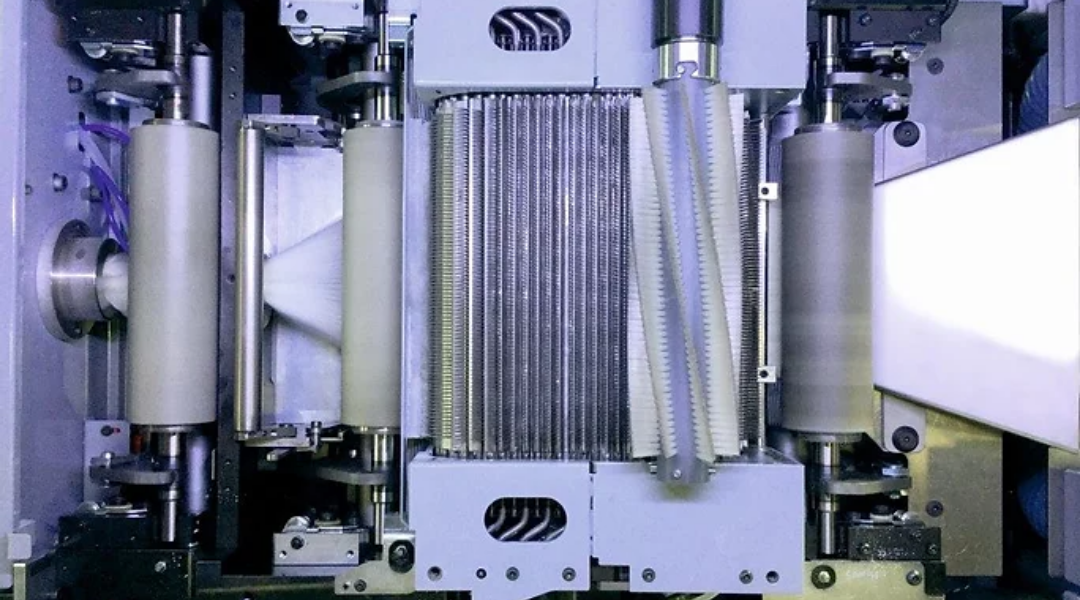

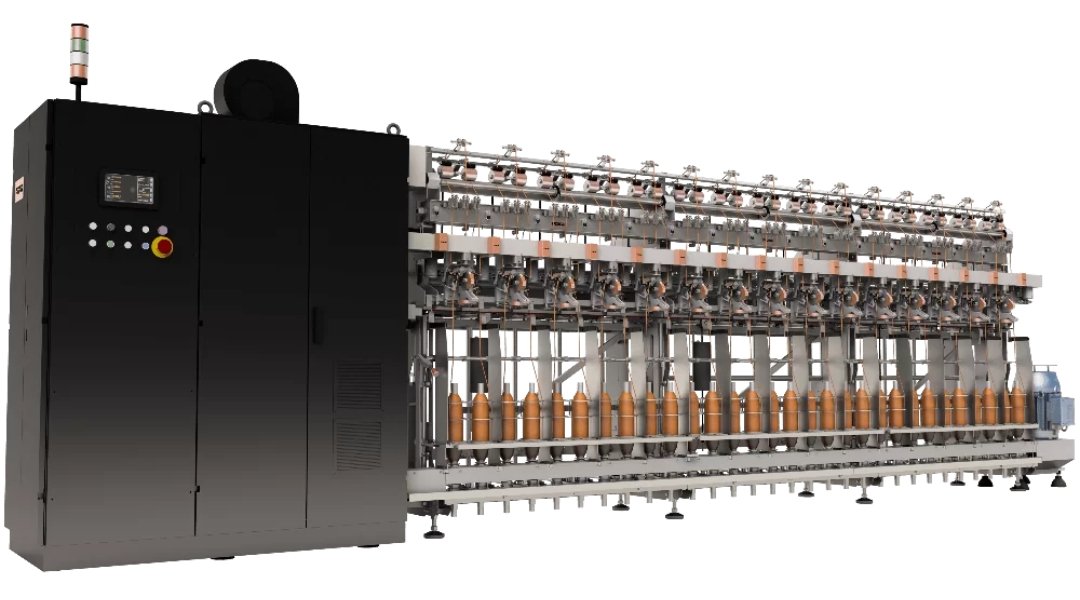

CD14 - Draft Head

CLV-GT

.png)

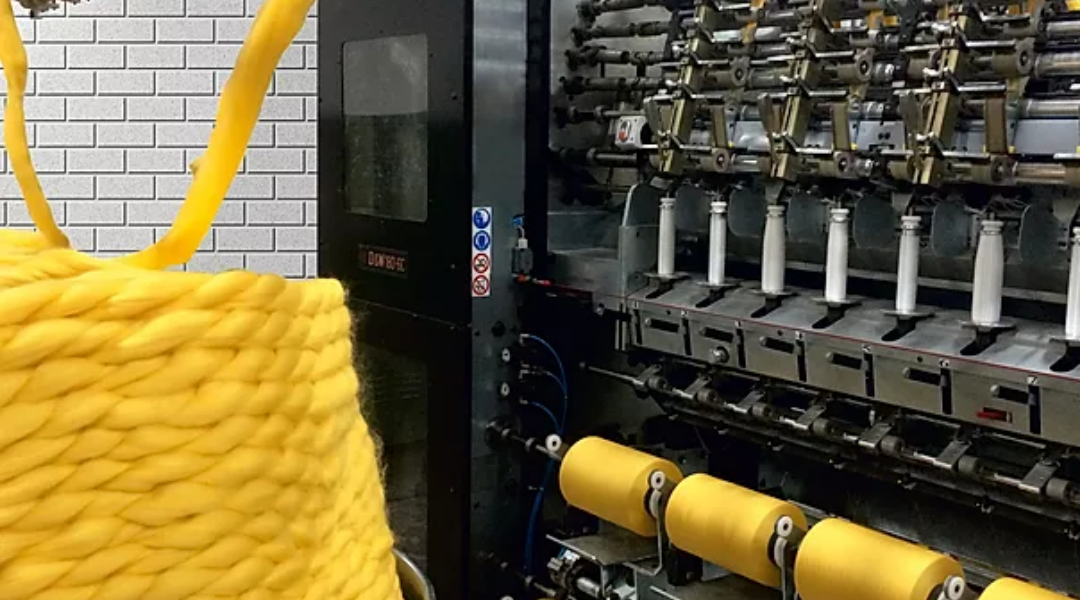

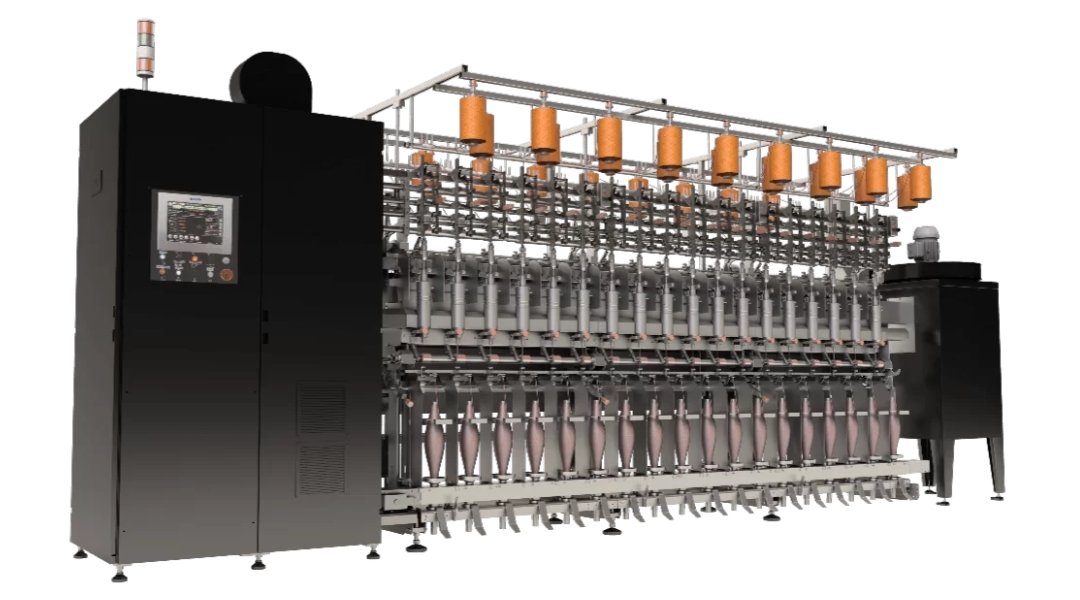

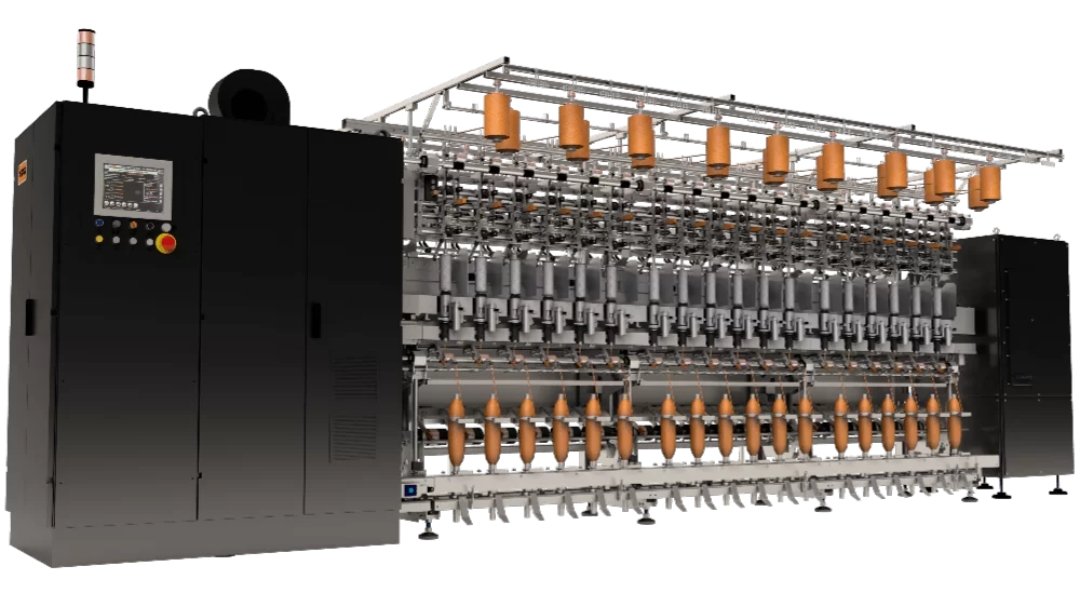

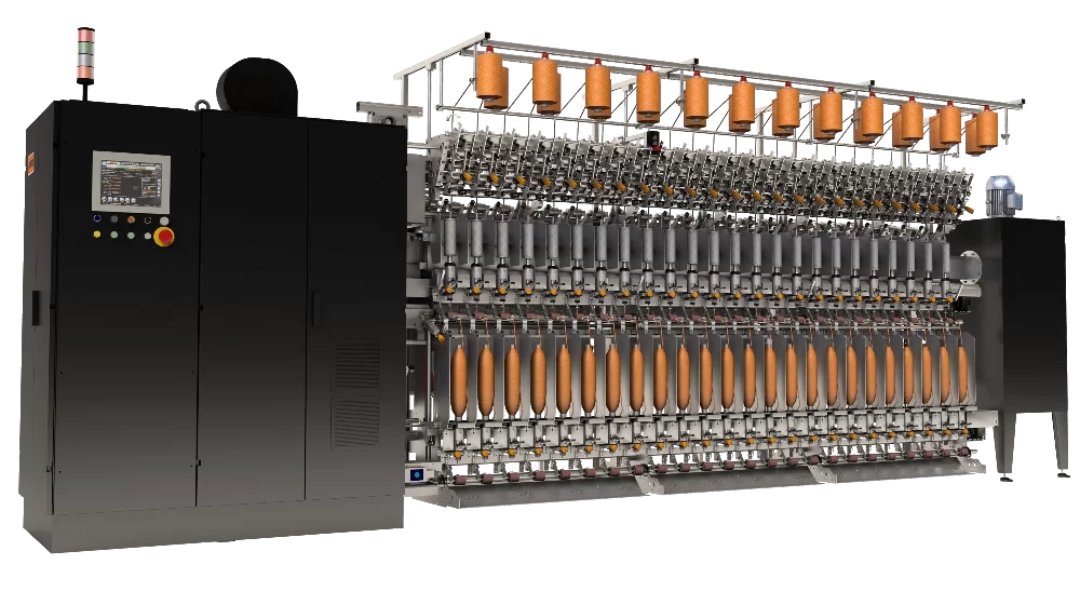

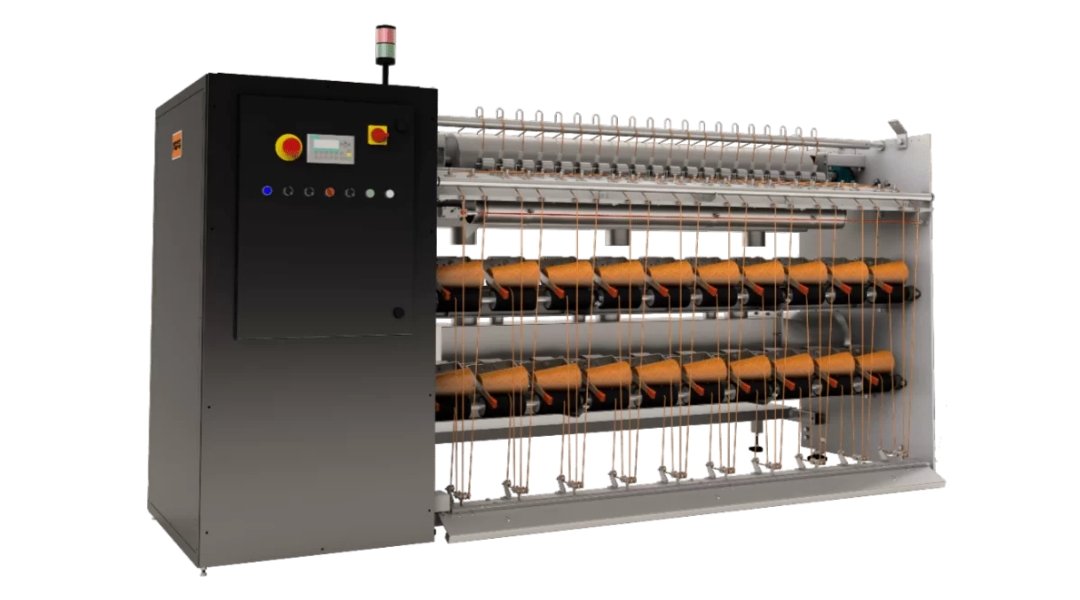

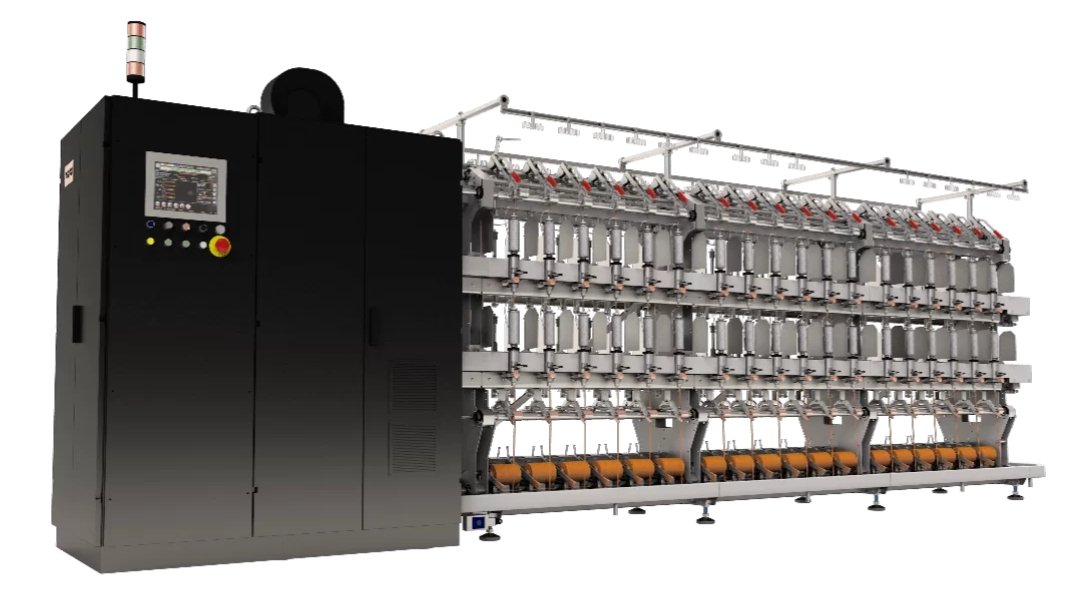

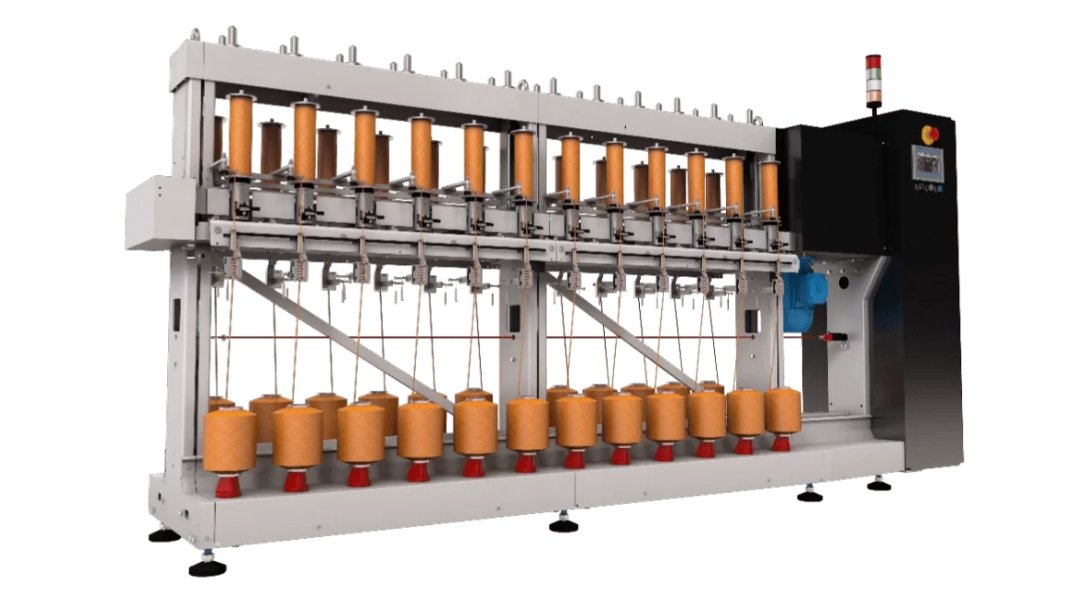

D&W (Draft & Wind)

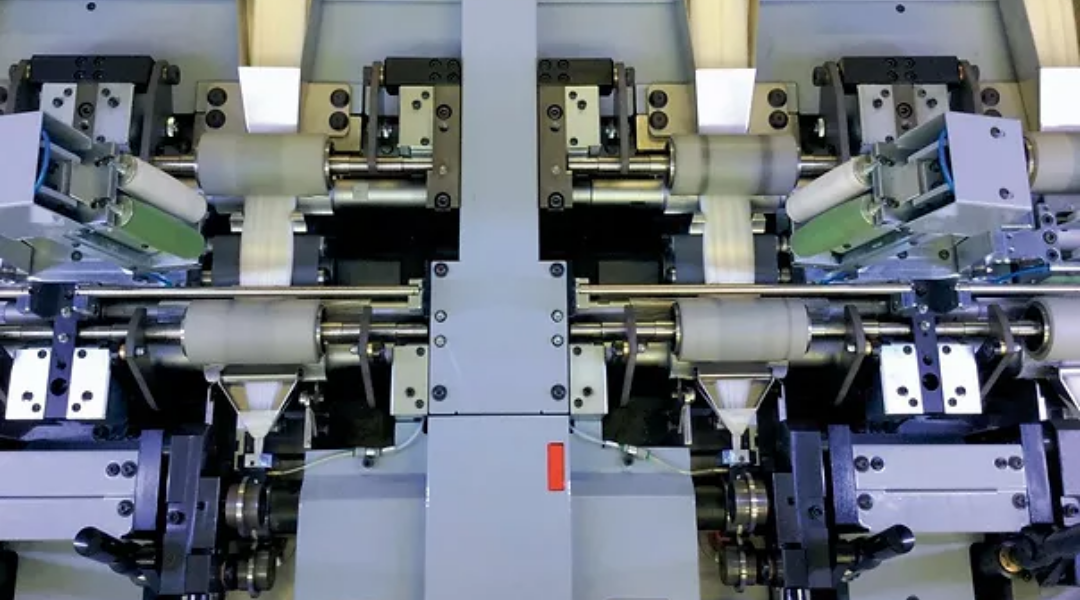

D&W Closeup

D&W

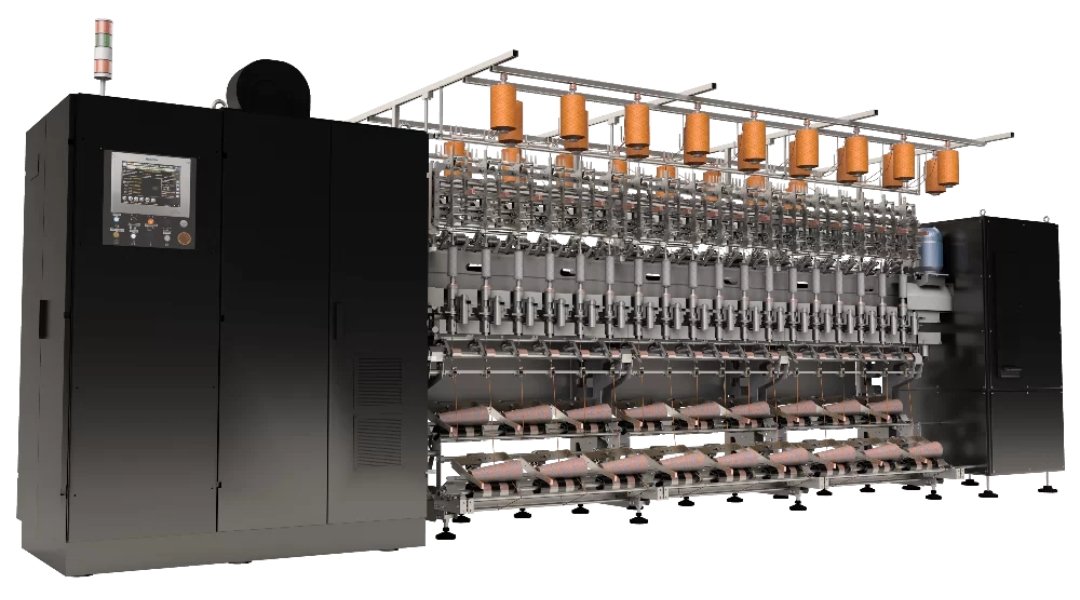

F6K03

FP03

FP19 - 1C

FPB03

FPK03 8C

FPT03

FST03

FU14

MH17E24 - Closeup

SD14 - Draft Head

TBR - DT

TBR DL - GLASS

TBR DL

TBR SC

Officine Gaudino offer a wide range of textile machinery, ranging from spinning machines for carded, combed and semi-combed. Since January 2009 the production of Lema Lezzeni has been acquired by Officine Gaudino S.p.A., and a new line of machinery for doubling and twisting has been created. In 2012 Officine Gaudino S.p.A. have developed a new concept for the production of basic yarn used for the production of open-ended rugs, creating the new D&W; we also have the complete range of drawers for combing, preparation for semi-combed and combed spinning of wool cut fibers.

Established in the mid 1920s by Pietro Gaudino, They initally developed small textile machines, then moved on to the construction of larger machinery such as fullers, wolf-cards, washes, twisting machines etc.

In the 1950's Dante Gaudino (the founder's son) started specializing in the production of ring spinning machines, abandoning other types. the first machines were made for spinning regenerated cotton (very requested at the time), followed by machines for spinning wool and other fine fibers, eventually also synthetic , chemical, celluloid, aramid, etc., Always in the woolen sector. In the past few years we have invented and patented new drafting sistems, winding systems, automatic doffing, bobbin changers, electronic interfaces, systems for linking to winders, sensors for detecting broken ends, roving breakers, systems for monitoring production, travelling cleaners, cleaners for the underwinding "mouse" etc.

Today, Officine Gaudino are managed by Piero, Roberto and Paola Gaudino, sons and daughters of Dante.

In 2009 we have acquired the brand LEMA LEZZENI s.r.l., known worldwide for the production of twisting machines, cops winders, fancy yarn twisters, drawing frames.

In 2008 we have also acquired "Atelier Houget Duesberg Bosson s.a. 1823" from Vervier (Belgium) in partnership with the Bonino family: the spinning section was taken by Officine Gaudino, while the carding machinery section is now owned by Bonino Carding Machines s.p.a..

Website: https://gaudino.com/

Wool, Cashmere, Synthetic fibers, Specialty natural fibers (Camel Hair, Mohair, Alpaca, Yak, etc.)

Highlights & Benefits:

- Precision-engineered feeding cylinders (Ø 108 mm) ensure gentle fiber control and consistent yarn quality.

- Minimizes irregularities and enhances Uster and CV values.

- Advanced AC drives with inverters for fine-tuning of speeds and optimal machine performance.

- Intuitive touch-screen control panel for real-time monitoring and operational management.

- Ergonomically designed side doors for effortless cleaning and maintenance, reducing downtime.

Wool, Cashmere, Mohair, Silk, Selected synthetic fibers

Highlights & Benefits:

- Large-diameter breast with six workers/strippers for gradual fiber processing and minimal breakage.

- Upgraded de-burring system with three burr beaters and larger Morel cylinders enhances cleaning and fiber quality.

- Removable brush cylinders simplify maintenance and improve operational efficiency.

- Integrated dust suction chutes optimize airflow and maintain clean fiber handling.

- Feeding cylinders with precision needle bushes and double transport points enhance fiber control and blending.

- AC motor-driven system allows exact speed adjustments for top performance.

- Improved can coiler ensures easy handling and minimal maintenance.

- Side doors provide quick access for cleaning and servicing.

Wool, Mohair, Synthetic fibers

Highlights & Benefits:

- Large-diameter breast with five workers/strippers for gentle fiber processing and improved throughput.

- De-burring system with three burr beaters and expanded Morel cylinders (Ø 650 mm) ensures superior cleaning and fiber integrity.

- Easy top-access brush removal reduces maintenance time.

- Integrated dust suction chutes improve airflow efficiency and simplify maintenance.

- Optimized feeding cylinders for wool and synthetic fibers; double transport points for wool and double delivery doffers for synthetics.

- Advanced AC drives provide precise speed control for consistent performance.

- Redesigned can coiler and side doors streamline operations and maintenance.

PAFA Spinning Machines

PAFA machines are designed for both large-scale industrial production and smaller artisan-focused operations, providing unmatched flexibility and efficiency. Equipped with advanced Siemens automation, these machines are fully compatible with Industry 4.0 standards, ensuring smooth, modern production processes.

- Seamless Integration: Easily connects with management software and barcode systems for precise production tracking.

- Data-Driven Management: Collects, monitors, and analyzes production data across all connected machines for optimized performance.

- Remote Support: Offers remote troubleshooting, training, and expert guidance, minimizing downtime and maximizing productivity.

Airjet

Babycombi

Banchino Flyer

Combifil

Combifil SW

Expo 80

Expo 2000

Fancycolor

Fancyframe

FT Chenille

Legafil 100

Legafil 400

Modular Machines

Raising Dual Mode

Raising F20

Rocfil

Spirafil

TA Twisting Machine

Winding BC 200

Website: https://pafasystem.com/